DIY Universal Intake Insulation Wrap

Although there is some validity to heat soak with aluminum

cold air intakes, there are some cases where I believe an intake wrap is just

dead weight on the car. Most forced induction cars should not benefit from

the wrap.

This is because when the air is compressed by the turbo it

heats up which then gets cooled by the intercooler. So a few degrees is

not going to make a difference if the air is just going to get super heated and

then cooled again.

Stock intakes generally don't benefit because the materials

are PLASTIC. Plastic has a low specific heat and air traveling inside the

intake can cool it down pretty quick. In addition, most of these lengths

are short or too complex to wrap.

I'd like to really question all those people who use heat

reflective tape. Maybe if heat was BLASTING on the intake, then a heat

reflective tape might work ok, but as far as I know, COOL air is supposed to

surround the intake. Also a flow of cool air rushes into the engine bay at

high velocities while driving.

So what's the purpose of an intake wrap?

Well I believe the only reason to use one is if you have a

LONG aluminum cold air intake and you do a lot of daily driving.

While your car is at a stop, heat builds up in the engine bay

and this heat will transfer to the intake making it very hot to touch.

When you accelerate, the hot intake tubing heats the moving air inside the

intake so it becomes less dense. As a result you may notice a little less

power or perhaps nothing at all. The same concept is found in your home

with an air conditioner that has an air duct going through a hot attic and into

a room. Well if you insulate the duct going through the hot attic, well

this means cooler air will reach your rooms.

So from my understanding, if you've got a heavy material with

a high specific heat surrounding your intake air path, it's going to store heat

and then that heat will seep into the air ingested by your car. Thus,

ideally one would want the following in an intake wrap:

In early July 2008 I consulted an industrial insulation expert

who gave me tips on finding the best CAI wrap material available.

What he described to me didn't exist, which means I'd have to

make it myself. However he told me what one guy does on industrial air

compressors that works great:

A company called ArmaCell makes high quality insulation foams.

I can take one of their products called ArmaFlex in 1/8" to 1/4" thick sheets,

then laminate them with Aluminum or Mylar. The end result will be a

thermal insulation foam with a protective layer on the outside.

What I would like to make is my Armaflex/Mylar hybrid

material, however my supplier can only give me 588 square foot rolls. This

means I'd have to shell out a lot of money just to start selling this material

to the public.

The retail cost might end up being about $4 per square foot,

while the average intake may require about 4 square feet.

With this type of money ($16) many frugal internet buyers will

simply turn to their home depot or refrigeration supply stores for some

"similar" materials so they can make their car look like a home improvement

store abomination like my intake below. I know for a fact nobody will buy

this which is why I'm not going to sell it.

Instead I'm going to run some tests, and maybe use my sample

materials to see how much an effect heat soak has on a long CAI in daily

driving.

The first test uses Home Depot material reflectrix ($20) for

smallest roll they had. 3M high temp duct tape $7.

| Disclaimer:

Please don't try anything stupid (like start a fire) by putting something in

your engine bay that shouldn't be there. We would like to stress the

importance of following automotive safety standards and using your own

judgment when modifying your motor vehicle. If you think you can do this

yourself and go to Home Depot for some cheap insulation please understand

the RISK involved when attempting to put "home improvement store"

modifications in your motor vehicle. We accept no liability for any

damages, personal or property, if you try this at home. |

| Problem: How do I

reduce the intake air temperature of Cold Air intake automobiles? |

| The Solution: Thermal insulation wrapped

around cold air intake tubing to achieve an air tight sleeve that is

non-adhesive, inexpensive, and safe to use in a hot engine bay.

Overview: When monitoring my intake air temperature (IAT) I've

noticed that there is a steady rise in IAT at idle on hot days. When

my car is parked at a stop light, it is not uncommon for the IAT to rise to

145 degrees or more. When this happens I can feel the car bog down off

the line as if it's breathing nothing but hot air. So my solution is to

"insulate" the cold air intake system so that heat from the engine bay does

not seep into the intake air. The end result is it takes longer for

the IAT to rise at idle on hot days, and the IAT temperature is more

stabilized being isolated from the heat of the engine bay.*

*Based on personal craftsmanship and materials,your

mileage may vary.

|

|

For making the Intake sleeve "air tight", I used this high

temperature resistant tape. It has great tack and makes an air tight

seal which is what I'm shooting for. For maximum protection, you may want to

try an aluminum tape though this will be more expensive. |

|

I am very hesitant before I put anything "innovative" in my

car, so with a butane lighter stick I try to melt and burn the material with

an almost 2000 degrees F flame. I concluded that the tape ends up

melting and doesn't catch fire which is good. The un-cured exposed

adhesive part of the tape WILL burn if put under direct flame though. |

|

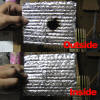

I put the test flame to my insulation material for 20

seconds. Since it is pure aluminum, it didn't melt or catch fire.

However the bubble wrap area around the flame did shrink and left a void of

gooey polypropylene. |

|

What is amazing is the opposite side of the insulation

looked flawless while the flame burnt side was scorched with soot and the

sealed air turned into a gooey mess in an area the flame touched. I

decided that using this as a cold air intake wrap would be ok. I also

concluded that the material does in fact insulate temperature quite well. |